Packaging equipment SECURITY

A necessity. An obvious choice. Operating large-scale machinery in confined spaces requires a carefully planned setup. The goal? To prevent any unwanted incident that could have serious consequences for the operator’s health or for anyone nearby.

In Quebec, the Commission des normes, de l’équité, de la santé et de la sécurité du travail (CNESST) oversees machine safety regulations, including those for packaging equipment. Key reference standards include: CAN/CSA-Z432, EN 999, and NF EN 415-6+A1.

Key STEPS

![]()

Risk

analysis

![]()

Inherent safety

![]()

Limiting access to the hazard zone

Risk

ANALYSIS

First and foremost, it’s essential to identify potential hazards. This step helps determine the concrete measures required to eliminate or reduce risks.

Inherent

SAFETY

From equipment setup to machine configuration, several measures can be implemented to minimize risk:

- Minimum clearance between the carriage and the floor

- Clearly defined work zone

- Table speed limitation

- Minimum clearance between the moving pallet and the machine’s fixed parts or nearby fixed elements

Limiting access

TO THE HAZARD ZONE

When necessary, additional safety measures can be put in place to effectively protect high-risk areas, such as:

- Perimeter guards with physical barriers

- Integration of an electro-sensitive protective device to complement the physical barrier

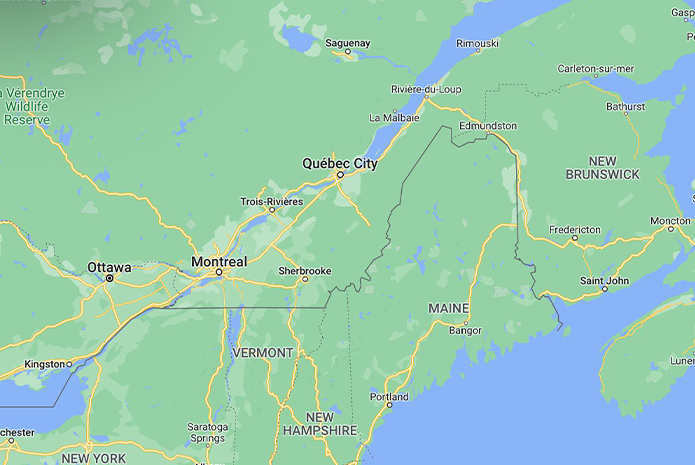

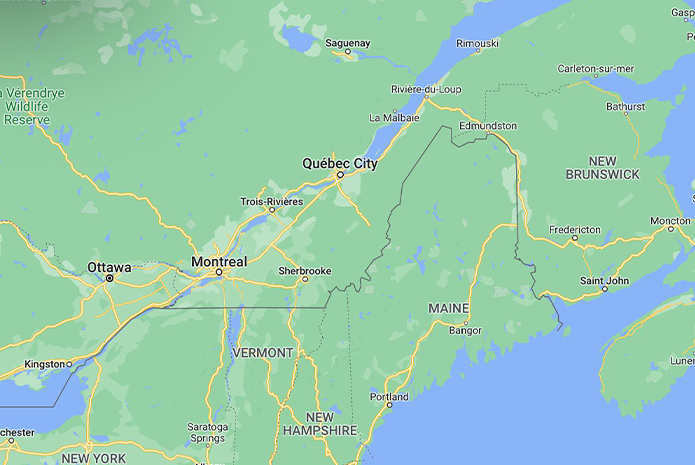

Anywhere in QUEBEC

No matter your needs, capabilities, or industry, our technicians are here to support you. With our mobile units and service truck, our technical team covers all of Quebec and can reach your factory or warehouse quickly. We also operate in the Ottawa region.