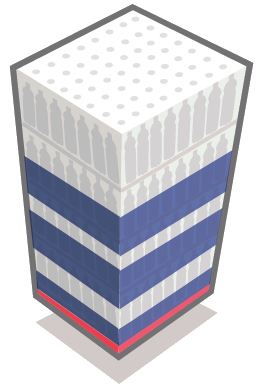

The Robopac distinction: Cube Technology

Robopac’s Cube Technology can help you save from 30% to 55%. Its hyper-sophisticated parameters allows you to use just what you need, at the most strategic points. Discover the four points that make it work.

If Robopac is a world leader today, it is thanks to the efficiency, reliability and robustness of its stretch film machines. It is also due to the fact that the company is constantly developing cutting-edge technologies. Each year, it reinvests close to 6% of its turnover in R & D (research and development).

This massive commitment to R & D has enabled Robopac to ideally position itself in the market and create revolutionary technologies such as Cube Technology. This exclusive innovation results in savings of 30% to 55%!

Cube Technology works in four ways to establish the optimal process for each pallet. With this fine-tuning, it is possible to use only strict amount necessary of stretch film. This translates into significant consumables savings and increased packaging reliability, which reduces damage during shipping.

To achieve this result, the technology addresses four key factors:

|

|

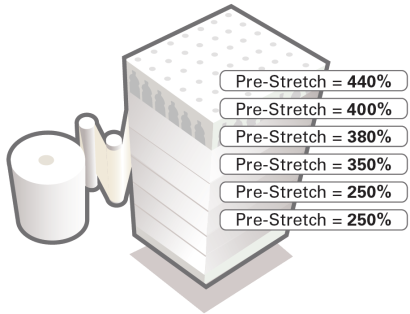

Multi-Level Variable Pre-StretchCube Technology guarantees the best film economy by ensuring the optimal pre-stretch for each level of the pallet. The pre-stretch can be adjusted up to nine times on each load, so that it can be lower at the all-important base of the pallet and higher at the top and thus apply less wrap. |

|

|

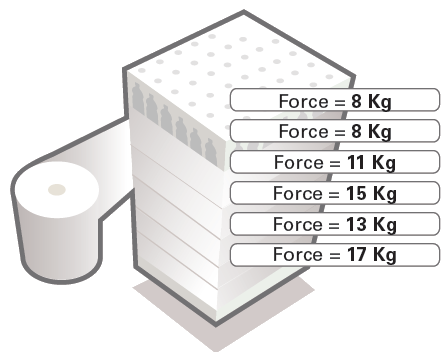

Multi-Level Variable Containment ForceThis technology also allows for the modification of the stretch film containment force at various heights. This is ideal for pallets that contain different-sized products, and those that require more containment force at certain levels. |

|

|

Strategic Wrap PlacementCube Technology allows you to place the film exactly where it has the most impact on load stability and containment, which is ideal for double stacking for example. |

|

|

Pro-Active Corner CompensationThis system combines the latest variable strength motor technologies to handle corners and adopt the appropriate application force to avoid damage or cause repetitive wrap breaks. |

SIGNIFICANT BENEFITS

- Reduces stretch film consumption.

- Improves pallet containment.

- Reduces up to 40% of damage to packaged products.

Learn more about our Robopac offer. Click here or contact us.

The Cartier team also suggests

Equipment

Categories: Equipment

ERGONOMICS AT WORK, WHY GO WHITHOUT!

The well-being of your employees at work is a critical issue for most companies: among other things, it motivates employees to perform their tasks as well as possible. In times of labor shortage, it becomes even more important to take care of your employees in order to keep them for a long time. With few employees in the job market and multiple offers, they can afford to raise their expectations. This is why working conditions are becoming primordial, and why employers are trying to differenciate themselves from each other. It is possible to improve these conditions in several ways, starting with adapting the various workstations to make them ergonomic and safe. Here’s how to improve the ergonomics of your work place to reduce the risk of musculoskeletal disorders (MSDs) among your teams.

Equipment

Categories: Equipment, Technical

Most popular equipment used by manufacturers

Shortage of labor being greatly felt in most industries, many of our clients decide to go for automation to save time but also to reduce work pressure on their current employees. We cannot deny the fact that the greater the need for manpower, the more employees have to fill this gap by working harder. Therefore, many companies decide to invest in automatic or semi-automatic equipment. Obviously, some machines are more popular than others, for several reasons. Very often, semi-automatic equipment is the first choice of clients as the initial investment is lower.

Equipment

Categories: Equipment

Take advantage of our sales to optimize your operations!

All or our Robots S6 are now on sale! The equipment is in stock, so it’is ready to be delivered and get started into yout operations. Buy now and avoid the 4% to 8% price hikes scheduled for July 1, 2021.