Existing packaging optimization

Achieve maximum cost-effectiveness

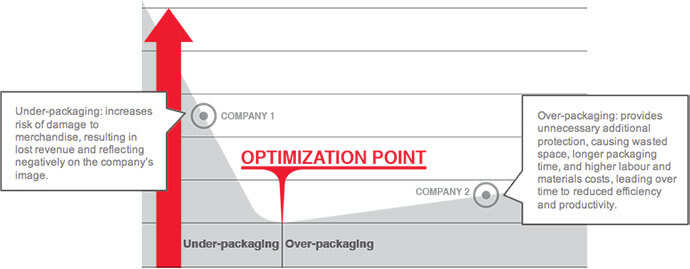

According to the Joint Industry Unsaleables Report, improper packaging is responsible for a 2% loss in companies’ net sales. This loss originates in incorrect assessment of packaging needs, frequently resulting in under or over-packaging.

Following a certified scientific methodology based on simulations and adapted to your environment, our laboratory experts determine the optimization point of your packaging process and implement the best solution.

Measurable Benefits

Advantages of addressing an under-packaging issue:

- Fewer losses related to damaged merchandise or late delivery

- Lower return shipping costs

- Increased productivity and profitability

- Guaranteed coverage of your merchandise by major carriers

- Protected brand image

Advantages of addressing an over-packaging issue:

- Considerable cost reductions

- Increased productivity and profitability

- Less waste of resources (packaging components, labour, energy, etc.)

- Reduced carbon footprint (less waste generated)

ISTA-certified, stringent process

CARTIER’s laboratory uses specialized equipment to recreate your shipping (air, land or sea), storage and handling conditions to detect and help you address any packaging weaknesses.

Built according to International Safe Transit Association (ISTA)-certified test protocols, our laboratory faithfully recreates your merchandise packaging and shipping processes by simulating the actual conditions of your environment.

Using advanced simulation equipment, our laboratory can test the following parameters:

- Vibration

- Impact

- Shock

- Elasticity

This means that our recommendations are validated by a process that makes it easier to obtain coverage from major carriers, among many other benefits.

Join the more than 40 companies in industries across the spectrum that have already optimized their packaging processes!

On Our Radar

Laboratory

Categories: Écoresponsabilité, Laboratory

Customer examples that speak for themselves!

In addition to responding to different requests and constraints, our team is committed to always keeping eco-responsibility in mind, enabling our customers to reduce their components, their costs and their GHGs – yes, their GHGs!

Laboratory

Categories: E-commerce, Laboratory, Testimonials

Webinaire e-commerce : apprendre du succès de J.E. Mondou !

Le virage est amorcé, le consommateur est connecté plus que jamais et l’évolution du commerce électronique touche désormais les industries de partout. Serez-vous en mesure de vous adapter et de vous assurer de performer sur ce nouveau terrain ?

Laboratory

Categories: Laboratory, Press Release

CARTIER Joins Amazon’s APASS Network: A First in Quebec’s Packaging Industry

CARTIER, the packaging specialist, has been admitted to the Amazon Packaging Support and Supplier Network (APASS), an exclusive group of Amazon-recognized ISTA laboratories. In joining APASS, the company consolidates its role as the preferred partner of Quebec companies already selling their products online via Amazon or considering doing so.